THÔNG SỐ KỸ THUẬT CỦA MÁY TẠO KHÍ NITƠ HÀN QUỐC WON-HI-TECH:

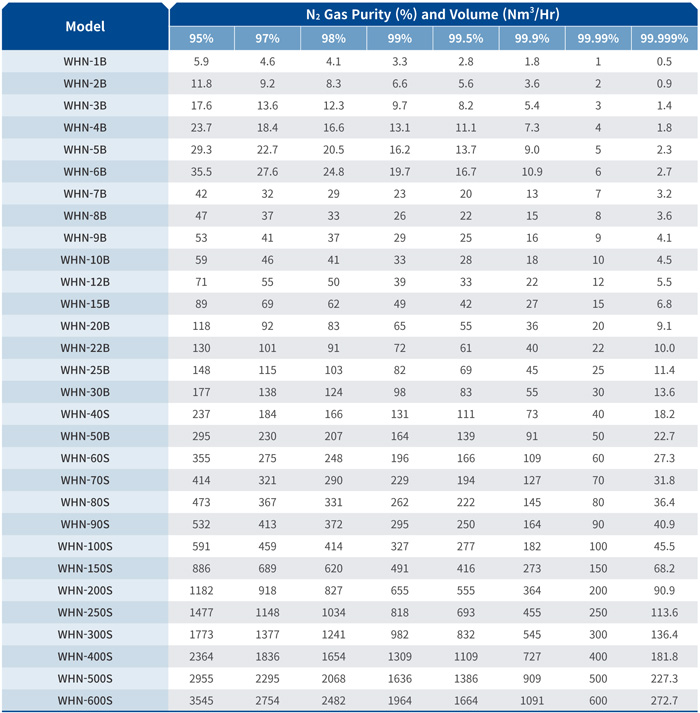

Performance Table for P.S.A. Nitrogen Gas Generator

Quick Information

- Place of Origin:Korea

Description

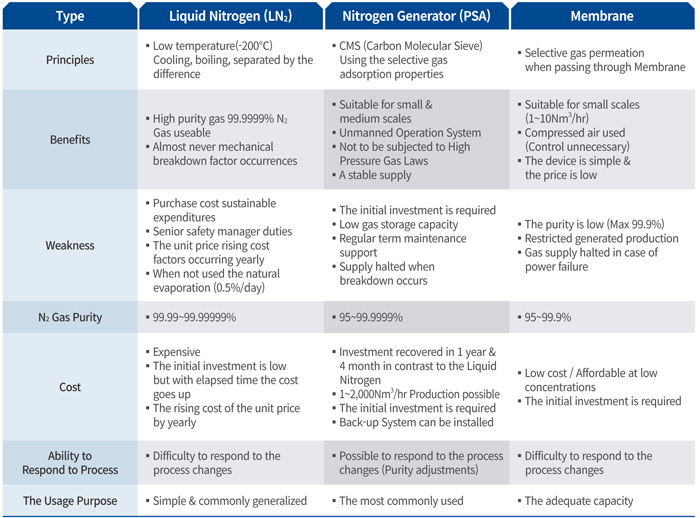

Pressure Swing Adsorption[PSA] Technology

Pressure Swing Adsorption(PAD) is a technology that can separate the sesired gas compounds by using the difference of adsorption force of the individual crystals fo gas from Molecular Sieve. In other words, adsoption may be defined as binding the gas molecules to the Adsorbent that is a solid substance through the suction force of the molecule.

A PSA system can separate the gas compounds by using the difference of adsorption force presented by the various chemical compounds or each individually. In the gas separation process, the compressed air passes through the Molecular Sieve layer composed of crystals with micro pores and the gases to be adsorbed becomes adsorbed by the adsorbent while the gas to be separated passed through the layer freely. The PSA Nitrogen Generator with the adsorbent called CMS (Carbon Molecular Sieve) phases in the compressed air filled with two or more adsorption towers that are moisture controlled, progresses the following steps that are repeated: compression → adsorption → decompression → purge to continuously produce the high purity Nitrogen.

A PSA system can separate the gas compounds by using the difference of adsorption force presented by the various chemical compounds or each individually. In the gas separation process, the compressed air passes through the Molecular Sieve layer composed of crystals with micro pores and the gases to be adsorbed becomes adsorbed by the adsorbent while the gas to be separated passed through the layer freely. The PSA Nitrogen Generator with the adsorbent called CMS (Carbon Molecular Sieve) phases in the compressed air filled with two or more adsorption towers that are moisture controlled, progresses the following steps that are repeated: compression → adsorption → decompression → purge to continuously produce the high purity Nitrogen.

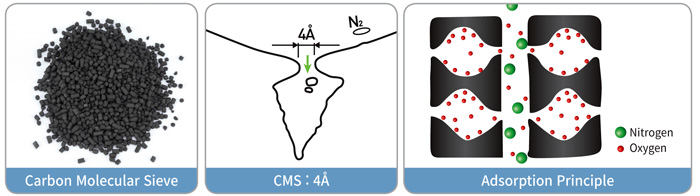

Hạt CMS - Carbon Molecular Sieve [Adsorption Principle]:

CMS is a 4Å crystal structure with a great number of micro pores made from the bark of a palm tree. Derived from the difference in diameter as the outer diameter of the Oxygen is 3.8Å while the outer diameter of the Nitrogen is 4.2Å, the adsoption of Oxygen which takes a shorter amount of time is understandably used. Moreover, the product that can maintain a certain compressive strength and a uniform pore structure must be selected in order to produce high purity Nitrogen.

- Implementation of a compact product with a simple structure derived from the best optimized design

- Implementation of the autonomous/unmanned operation controlled electronically

- Affordable pricing due to the On-Site(site production) method of direct production using compressed air-Not to be effected by the price fluctuations or the delivery delays as liquid Nitrogen

- Designed to adequately reflect customization according to the user required specifications depending on the conditions of the Nitrogen purity, production pressure and etc.(Up to 95~99.9999%, 1-600Nm3/hr)

- CMS which is an adsorbent used in gas separation is semi-permanently usable

- Not to be subjected to the High Pressure Gas Control Act as the operation is handled at low pressure compared to high-pressure gas and no legal obligation needed concerning the gas storage vessel managed by the designated senior safety personnel(s)

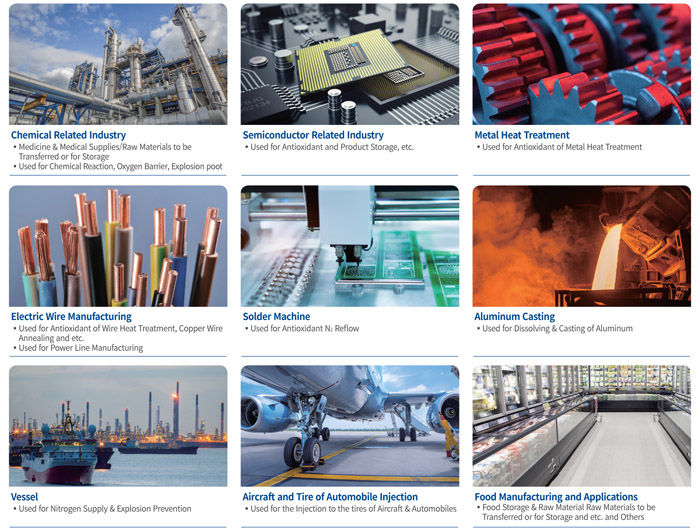

Ứng dụng của khí nito: Nitrogen Generator Applied Field

Membrane Type Nitrogen Generator

Membrane used for gas separation uses the principle of the selected gas permeation related to Membrane. Membrane Type Nitrogen Generator will use materials such as Polyimide and Polysulfone as the relative solubility of each gas composition and permeability for different substances will appear differently.

The Membrane Type Nitrogen Generator of WON Hi Tech uses a hollow fiber gas separation Membrane which transmits more Oxygen than Nitrogen for an easier penetration. In other words, when the compressed air is passed through the Polyimide hollow fiber Membrane, the Nitrogen which passes relatively more slowly is passed through the high pressure side (inside the hollow fiber) while the Oxygen is passed through the low pressure side (outside hollow fiber) and hence discharged to the atmosphere.

The Membrane Type Nitrogen Generator of WON Hi Tech uses a hollow fiber gas separation Membrane which transmits more Oxygen than Nitrogen for an easier penetration. In other words, when the compressed air is passed through the Polyimide hollow fiber Membrane, the Nitrogen which passes relatively more slowly is passed through the high pressure side (inside the hollow fiber) while the Oxygen is passed through the low pressure side (outside hollow fiber) and hence discharged to the atmosphere.

Product Features of Membrane Type Nitrogen Generator

- Nitrogen can be obtained easily only with the dried compressed air.

- There is no noise occurrence as the transition of the adsorption/regeneration cycle is not necessary.

- Only the minimum space is used due to the small volume.

- It is permissible whether it is horizontally or vertically placed, either way.

- The active power of Nitrogen generator is unnecessary.

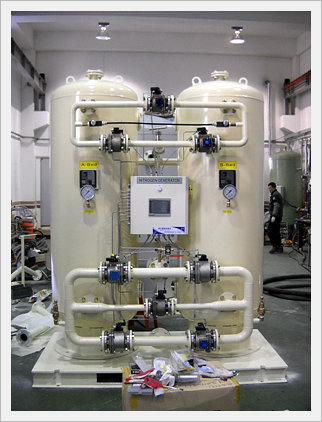

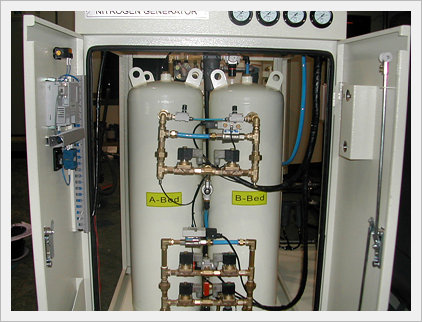

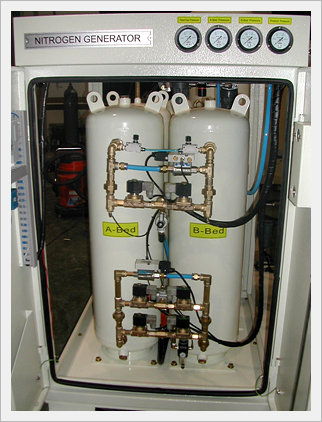

Product Image

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP BẢO TÍN

Địa chỉ: P.305- Tòa nhà C2 - đường Đỗ Nhuận - P. Xuân Đỉnh - Q. Bắc Từ Liêm - Hà Nội

Điện thoại: 0983 755 949 Fax: 043.7509008 Skype: phuong-pr Hotline: 0946 678 168

Email: maynenkhibaotin@gmail.com Website: maynenkhibaotin.com

UY TÍN – CHẤT LƯỢNG – GIÁ CẢ CẠNH TRANH – PHỤC VỤ 24/7

CHỊU TRÁCH NHIỆM VỀ CÁC SẢN PHẨM BẢO TÍN CUNG CẤP!